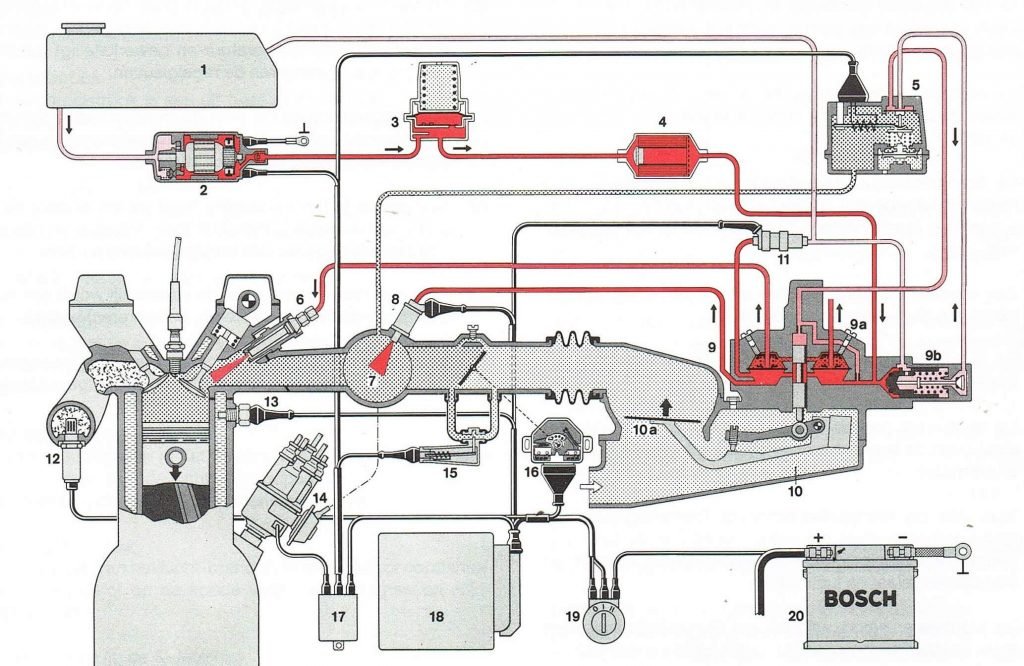

The Bosch K-jetronic system is made up of different components, which are discussed below and their functions. Only the components related to the system are shown below. The same categories can be found in the Shop area where the available parts are displayed.

The K-jetronic system belongs to the group of CIS injection system which stands for continuous injection system. This means that the fuel is continuously injected into the inlet manifold. The system is completely mechanical. From the end of 1979, this system was modified by adding a lambda control system (KA-jetronic). This system is shown in the figure below, the components 11, 12, 16 and 18 are specific to this lambda control system and are therefore not present in a mechanical K-jetronic system.

2 Fuel pump

The fuel pump is used to supply the system with the necessary fuel pressure. Just after the fuel pump, a non-return valve is installed which is needed to keep the system pressurised after the engine has been switched off.

3 Fuel accumulator

The fuel accumulator has 2 functions:

- After the engine has been switched off, the fuel system is kept under pressure by this accumulator to promote a warm start.

- The accumulator dampens out the fuel pulses generated by the fuel pump.

4 Fuel filter

The purpose of the fuel filter is to filter the fuel so that it does not pollute the system.

5 Warm up regulator

The purpose of the warm up regulator is to enrich the fuel mixture during a cold start. When the engine warms up, the mixture is depleted to the correct ratio.

This component can be overhauled, the necessary components can be found in the shop.

6 Injector

The injector provides a nicely atomised fuel so that the fuel-air mixture is as homogeneous as possible.

8 Cold start injector

The cold start injector, adds extra fuel at very low ambient temperatures.

9 Fuel distributor

The fuel distributor, has the function of supplying the different cylinders with exactly the same amount of fuel. Some versions have a fuel pressure regulator built in internally.

This part can be overhauled.

10 Air flow meter

The air flow meter measures the amount of air drawn in by the engine. Based on this measurement, the fuel mixture is mechanically adjusted.

11 Timing valve

This control valve is used with KA-jetronic systems. Here the fuel mixture is regulated by means of a lambda-probe control system. The control valve changes the pressure between the upper and lower chamber of the fuel distributor, thus changing the fuel mixture.

12 Lambda-sensor

The lambda-sensor (only on KA-jetronic) generates a signal that the control unit uses to adjust the fuel mixture. The lambda sensor only generates a signal if the component has a sufficiently high temperature.

13 Thermo time switch

The thermo time switch is used first of all to control the injection time of the cold start injector (8). If a lambda control system is fitted, this sensor is also used as an input for the control device (18).

15 Auxiliary air valve

The purpose of the auciliary air valve is to supply more air when the engine is cold. This air slide can be operated electrically or it is directly connected to the coolant system.

16 Throttle valve switch

The throttle switch is only used in systems with a lambda control system. This switch is present so that the control unit knows the gas position.

18 Control unit

The control unit (ECU) processes the various inputs to provide the desired signal to the control valve (11), thus optimising the fuel mixture.